If you are looking for a solution to simulate your Polyurethane (PUR) foam injection process, you are in the right place. REM3D®, was developed in tight collaboration with the industry, for the industry, and trusted to be the solution by leaders in PUR foam products. REM3D® is designed to handle the most challenging PUR foam injection processes. If you are not sure we can simulate your specific process, contact us, and we will work together to find a solution for you.

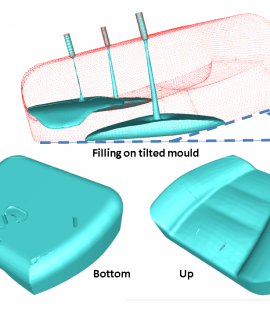

Car seat with moveable inlet