Optimize the Entire Manufacturing Process

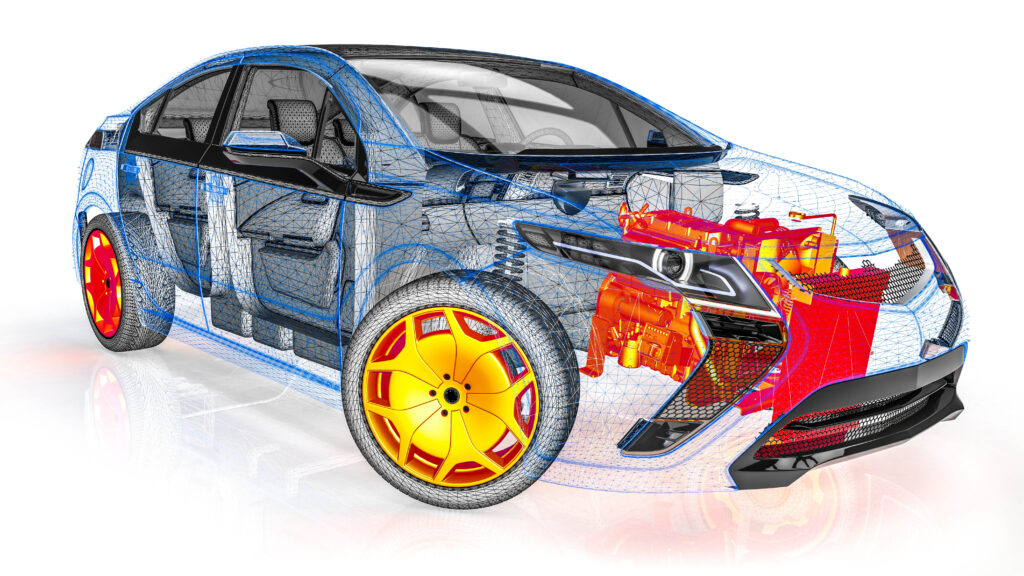

Pre-Forming Processes

Reducer Rolling, Cross Wedge Rolling

Forming Processes

Impression forging, Cogging, Rolling of long products, Ring rolling, Orbital forging, Bending, Superplastic forming (SPD), Saddling, Swaging, Thread rolling

Around the Forming Process

Induction Heating, Case hardening, Heat Treatment

Equipment Supported

All equipment, including custom-made, is supported. Most commonly used are: Mechanical press (using the actual die speed vs crank radius), Hydraulic press, Hammer, Counter-blow hammer