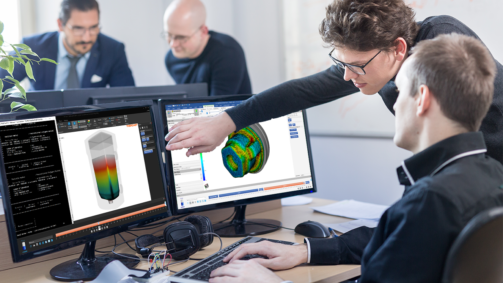

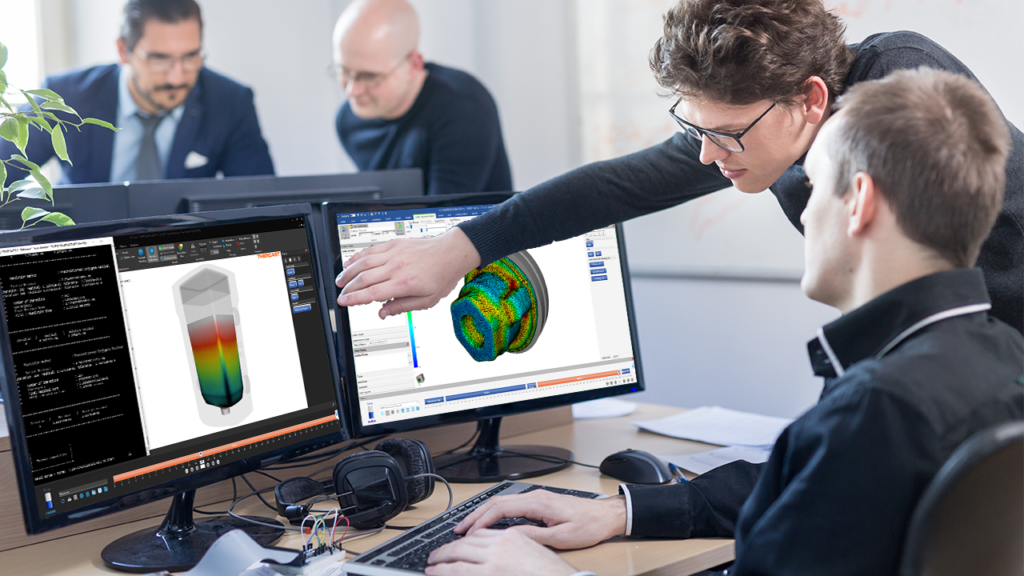

Transvalor Americas offers an extensive portfolio of high-performance simulation software that addresses a wide range and variety of forming processes, for metallic solid and liquid materials as well as for polymers.

Our simulation software brings significant engineering and manufacturing know-how to a number of industries.