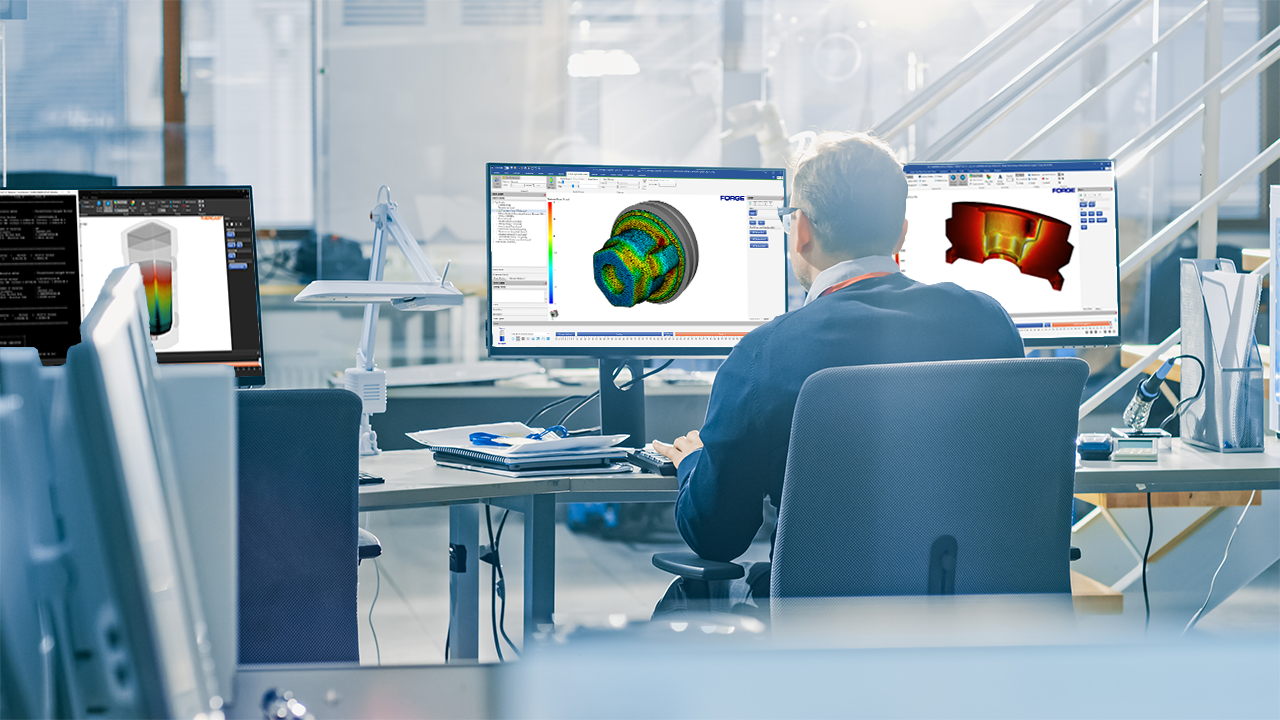

SIMULATION TIME RENTAL

As a customer under maintenance or in a lease agreement, you can easily address peaks and overload without investing in costly upgrades. With Transvalor, simply purchase hours of computation. All computations run on 12 cores, unless specified otherwise. We offer a standard 100-hour 12-core bundle and can customize a plan to suit your needs.

How it works:

- Prepare the simulation setup

- Send us your setup through a secure FTP site or through our Technical Support Contact Form

- Our team will review your setup and provide you with recommendations to ensure it's optimized and ready

- Our team will run the simulation on our servers

- Once complete, we'll send you the results and any additional information

- We'll send you updates and reminders throughout the process and reach out if/when there are 10 hours remaining to determine next steps.